How much does it cost to build a light steel villa house?

Light steel villa manufacturing cost analysis

:(due to exchange rate fluctuations, the price of this article are calculated in RMB, such as the need to calculate the real-time exchange rate of each country can be clicked on the accounting)

I. Cost range

▲ Basic classification price

Gross house (without interior decoration): about 1200-1400 RMB/square metre, covering only the main structure, exterior decoration, water and electricity pre-installation and other basic projects.

Fully-decorated house (including basic decoration): about RMB1,500-2,000/square metre, covering external decoration, doors and windows, heat and sound insulation and simple internal decoration.

High-end well-decorated house: using high-end materials or refined decoration, the price can be up to RMB 2,500/sqm or more.

◆ Typical house cases

Two-storey light steel villa of 200 square metres, total price about 340,000 RMB at 1,700 RMB/square metre;

The total cost of a heavy light steel villa (200 square metres) is about 336,000 yuan (1,680 yuan/square metre).

II. Cost Composition

▲ Material cost (30%-40%)

Light steel keel: core support material, RMB 3,000-8,000 per tonne, 25-35kg per square metre dosage, cost about RMB 75-280.

Wall materials: including OSB boards (RMB 40-80/sqm), cement fibre boards (RMB 50-100/sqm) and thermal insulation wool (RMB 100-300/m3), with a combined cost of approx. 150-250 RMB/square metre.

Auxiliary materials: such as fireproof coating, exterior decorative panels, etc., the price varies greatly depending on the material selected.

▲ Construction cost (30%-40%)

Labour cost: significantly affected by the region, about 400-500 yuan / square metre in first-tier cities, about 200-300 yuan / square metre in third and fourth-tier cities.

Construction period: the main construction of 200 square metres villa takes only 20-30 days, the time cost is significantly lower than the traditional brick structure.

▲ Foundation cost

The foundation cost of light steel villa is only 1/5 of that of brick-concrete structure, for example, when brick-concrete foundation costs 20,000 RMB, light steel only costs 10,000 RMB.

Foundation cost accounts for about 10-15% of the total cost, which is affected by geological conditions and design requirements.

▲ Design and other costs

Design cost: 5-10% for the optimisation of individual solutions.

Other miscellaneous items: including taxes, transport costs, acceptance fees, etc., accounting for about 5-10%.

III. Key Influencing Factors

▲ Regional differences: economically developed regions due to higher labour and material costs, the overall cost of the upward fluctuation.

▲ Decoration standards: the grade of interior materials (such as high-end tiles, customised furniture) directly affects the total cost.

▲ Construction efficiency: the mode of factory prefabrication + on-site assembly shortens the construction period and indirectly reduces the management cost.

Fourth, the cost-effective advantage

▲ Use of area: light steel villa wall is thin (12cm), 8%-15% more use of space than brick-concrete structure under the same floor area.

▲ Long-term cost: excellent thermal insulation performance (15cm wall ≈ 1m brick-concrete thermal insulation effect), reducing late energy costs.

custom Tiny Triangle steel frame villa

Maybe You Ask

1.Is it cheaper to build a light steel villa or a brick house?

Light steel villa: the offer is usually in the range of 1300-1500 RMB/㎡ (including external wall insulation, doors, windows, electric circuits, etc.), which belongs to the full decoration delivery standard;

Brick-concrete houses: the offer of rough frame is about 800 RMB/㎡, but you need to pay extra for external wall insulation, doors and windows, hidden project decoration, etc. If you pursue the same design complexity, the brick-concrete cost cost is higher.

The construction cycle of light steel villa takes only 30-60 days and is less affected by weather; brick and concrete takes 6 months to 1 year. light gauge steel frame house can save the cost of lost labour (e.g., $24,000) and on-site transport costs.

Long-term maintenance and adaptability (to learn more about light steel villa building maintenance you can refer to this blog of mine:How much does it cost to maintain a light gauge steel structure villa house?)

Brick-concrete houses: high durability, low maintenance costs, but difficult to adapt;

Light steel villa: stronger seismic and wind resistance, suitable for mountains, hills and other complex terrain, but wet areas need to pay attention to anticorrosion maintenance.

If fast occupancy, flexible modelling and high occupancy rates are sought, lightweight steel villas are preferable;

If the budget is limited and the geological conditions are stable, brick-concrete houses have lower short-term investment, but they need to bear the subsequent decoration costs.

Summary:

the overall cost of the two is close, but the light steel villa in the cost of time, space use, seismic performance and other aspects of more advantageous, suitable for the pursuit of efficiency and personalised users; brick houses for limited budget and the traditional structure of the user has a preference.

2.How long can the light steel villa be used?

The life span of light steel villa is affected by multiple factors. Comprehensive data from many studies show that its life span can be divided into the following intervals:

▲ Minimum guaranteed lifespan: 30-50 years (quality up to standard and maintenance in place)

▲ Conventional life expectancy: 50-100 years (using high-quality materials, standardised construction and regular maintenance)

▲ Extreme life expectancy cases: 70-100 years for some high-quality projects (e.g. steel with galvanised layer ≥ 275g/㎡ + professional maintenance)

To know more about the usage period of light steel villa you can read this blog of mine: How many years can I live in a light steel villa?

3.Are Light Steel Villas Really Fireproof?

4.Analysis of the advantages and disadvantages of light steel villa

5.Difference between light steel structure villa and wooden structure house

6.Are light steel villas really environmentally friendly?

Light steel villa has significant environmental advantages in material recycling, construction pollution control, long-term energy saving, etc., in line with the concept of sustainable development. Its environmental performance is mainly reflected in the low carbonisation of the whole life cycle (construction, use, dismantling), which is one of the preferred solutions for green building at present.

Analysis of light steel villa environmental protection:

I. Material environmental protection

▲ Recyclability:

The main body of the light steel villa is made of hot-dip galvanised steel, which can be recycled at a rate of more than 90% after dismantling, avoiding non-renewable rubbish such as cement bricks and tiles produced by dismantling of traditional buildings.

▲ Resource saving:

The energy consumption of steel production is lower than that of traditional building materials (e.g. cement), and the loss rate of materials in construction is more than 50% lower than that of brick-concrete structure.

II.Environmental advantages of the construction process

▲Low-pollution construction:

Prefabricated components are used in the factory, and on-site assembly reduces more than 70% of construction dust and noise pollution, which is in line with green construction standards.

▲ Land protection:

The self-weight is only 1/5 of that of brick-concrete structure, which reduces the excavation depth of the foundation and the amount of earthwork, and reduces the damage to the soil ecology.

III.Energy saving performance in operation period

▲ Highly efficient heat preservation:

The wall is filled with rock wool or polystyrene materials, with a low thermal conductivity of 0.035-0.045W/(m-K), saving 40%-60% energy compared with traditional brick walls.

▲ Reduced carbon emissions:

Lower energy consumption for heating/cooling, and about 30% less carbon emissions in the whole life cycle than brick-concrete houses.

IV. Environmental Comparison with Traditional Buildings

Indicator Light steel villa Traditional brick-concrete structure

Material recycling rate ≥90%1 ≤30

Amount of construction waste ≤0.03t/m21 ≥0.3t/m2

Annual energy intensity 40-60kWh/㎡(heating)1 80-120kWh/㎡

Demolition pollution risk Low (no chemical binder) High (contains cement and paint residue)

V. Controversies and Limitations

▲ Carbon footprint of steel production:

Steel smelting process still produces CO₂, but energy consumption can be reduced by more than 60% through recycling;

▲ Geographical adaptability:

Humid areas require enhanced anti-rust treatment, which may increase maintenance costs, but can be circumvented by selecting materials with a galvanised layer of ≥275g/㎡.

7.Ten core issues to consider before building a light steel villa building

Construction of light steel villa compared to traditional wooden villa and brick villa has saved a lot of heart, of course, encountered problems certainly more than ten, here in accordance with the author of more than 10 years of experience in the industry to the top ten problems need to be considered are listed below:

I. Material quality and standards

▲ Rustproof performance of steel:

Light steel keel needs to use steel with hot-dip galvanised layer ≥ 275g/㎡ to avoid rusting problems caused by poor quality steel (life shortened to 20-30 years);

▲ Parameters of insulation materials:

Third-party test reports should be requested to confirm the thermal conductivity of rock wool/glass fibre (should be ≤0.045W/m-K);

▲ Waterproof material durability:

Give preference to polymer waterproofing membrane rather than asphalt shingle to reduce the risk of leakage.

II.the construction team qualification and experience

Verify the qualification certificate of the construction team, and give priority to enterprises with special construction qualification for light steel villa;

At least 3 cases of similar projects are required, focusing on the accuracy of keel installation and the level of hidden engineering treatment.

III.Foundation treatment and geological suitability

Geological exploration is carried out in advance, and the soft ground foundation needs to be reinforced by pile foundation or replacement method (the cost increases by 15%-30%);

The foundation drainage system needs to be designed with drainage ditches with a slope of ≥3% to prevent water from accumulating and leading to settlement.

IV. Design Planning and Geographical Adaptation

▲ Functional layout:

Staircase slope ≤35°, corridor width ≥1.2m (adaptable to the needs of the elderly/children);

▲ Climate adaptation:

Rainy areas need to strengthen the roof waterproofing (slope ≥ 30 ° + double-layer waterproof layer), alpine areas wall insulation layer thickened to 150mm.

V. Contract terms risk avoidance

Clarify the material brand, specifications and unit price (such as light steel keel thickness ≥ 1.2mm);

Agree on the upper limit of incremental cost (suggested ≤ 5% of the total cost) and quality warranty period (main structure ≥ 20 years).

VI. Maintenance cost and cycle

The estimated average annual maintenance cost is 0.8%-1.2% of the construction cost (including the replacement of roof sealant and refreshing of anti-rust coating);

Wet areas need to check the rust and corrosion of keel joints every 3 years.

VII. Environmental Performance and Energy Consumption

Verify the formaldehyde emission of rock wool/glass fibre (≤0.08mg/m³);

Measure the heating energy consumption (recommended ≤ 60kWh/㎡ -year), and give priority to three-layer insulating glass windows.

VIII. Verification of Disaster Resistance

The structural design is required to meet the standard of 9-level seismic and 12-level wind resistance, and the shear strength of the verification bolts is ≥8.8 level;

Additional wind-resistant anchor bolts (spacing ≤1.5m) are required in typhoon-prone areas.

Nine, sound insulation effect optimisation

Walls are filled with noise-reducing rock wool (density ≥80kg/m³), and floor slabs are fitted with sound insulation pads (impact sound pressure level ≤65dB);

Avoiding the design of water pipe/line pipe through the beam to reduce the sound transmission from the structure.

X. Comprehensive cost comparison

Measure the full life cycle cost (including 30 years maintenance costs), and the traditional brick-concrete structure comparison premium should be ≤ 15%;

Beware of low price traps (<1200 yuan / square metre offer usually exists material shrinkage risk)

If you have more questions, feel free to contact us by email for a free consultation.

Email:export@qxgg.com

tiny triangle steel frame villa

Why Choose Us

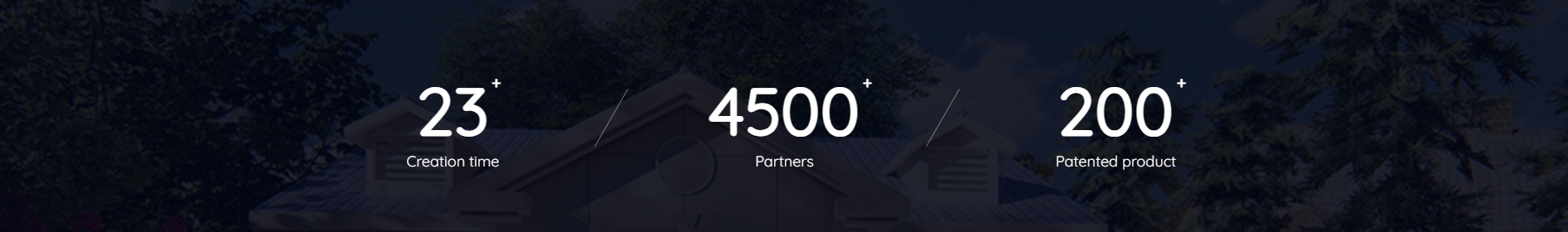

Shijiazhuang Eiffel Steel Structure Co., Ltd.

Shijiazhuang Eiffel Steel Structure Co., Ltd. is an enterprise dedicated to researching and developing new energy-saving and environmentally friendly houses and construction methods. We always adhere to the values of honesty and quality first, and position ourselves as a leader in high-quality steel structure villa construction. We combine emerging foreign technologies with the actual domestic market and provide customers with one-stop services for prefabricated buildings such as design, production, interior decoration, and whole house customization. The prefabricated buildings produced by the company are widely used in office buildings, villas, rural courtyards, estate clubs, tourist attractions, homestays, hotels, public facilities, etc.

At present, the company is centered in Shijiazhuang, Hebei Province, with products radiating to regions such as Beijing, Tianjin, Hebei, Shanxi, Shandong, Henan, Liaoning, Mongolia, Jiangsu, Sichuan, and Guangxi, and exported to overseas markets. Adhering to the quality demand of "building a century old villa, choose Eiffel", we strive to create an excellent brand of prefabricated buildings.

House building process

Helping customers maximise value with consistent excellence