Assembled steel structure shopping mall building steel structure commercial metal building

Assembled steel structure shopping mall building, steel structure commercial metal building, reshapes the efficiency and sustainability of commercial spaces. As a professional supplier of prefabricated steel structure buildings, we focus on providing efficient, environmentally friendly, and scalable solutions for commercial complexes.

Assembled steel structure shopping mall building steel structure commercial metal building

Assembled steel structure shopping mall building, steel structure commercial metal building, reshapes the efficiency and sustainability of commercial spaces. As a professional supplier of prefabricated steel structure buildings, we focus on providing efficient, environmentally friendly, and scalable solutions for commercial complexes.

I. Core Product Advantages: Materials, Parameters, and Differentiated Design

Material Processing

The main structure utilizes Q235/Q355 high-strength steel, meeting GB/T 700-2006 standards and achieving a tensile strength of ≥375 MPa. The exterior wall system utilizes a composite structure of galvanized steel and gypsum board/corrugated sheeting (70 mm thick). The surface is coated with high-voltage electrostatic powder coating (coating thickness ≥46 μm, using Akzo Nobel or Tiger paint), providing corrosion resistance for over 15 years. The interior is filled with 100 mm thick rock wool board (thermal conductivity ≤0.045 W/(m·K)), meeting Class A fire protection requirements. Specifications

The standard module dimensions are 12m × 24m × 8m (span × length × floor height), supporting horizontal and vertical expansion, with a maximum single-story area of 5,000 square meters. Each unit weighs 8-12 tons, has a load capacity of 500kg/square meter, and is wind-resistant up to 12 degrees and seismic fortification intensity 8. It has been certified by the China Academy of Building Research.

Features

Fast Construction: Utilizing bolted connection technology, on-site installation speeds reach 200 square meters per day, shortening construction time by 50% compared to traditional construction.

Eco-integration: Optional solar photovoltaic panels (280W/square meter), rainwater recycling systems, and ground-source heat pumps reduce operating energy consumption by 30%.

Spatial Flexibility: Adjustable steel columns and modular partitions support dynamic commercial space layout adjustments.

II. Customized Service Process: Full-cycle management from requirements to implementation

Requirements Communication

BIM digital modeling services are provided, allowing customers to adjust floor heights, column spacing, and functional zoning (e.g., atrium, cinema, supermarket) online. Optional materials (fluorocarbon-coated aluminum panels/brushed stainless steel panels) and special structures (cantilevers, domes) are available.

Production and Delivery

Utilizing an intelligent production line, the tolerances are controlled within ±3mm. Production cycles are 20 days for standard modules and 30 days for customized modules. We support combined sea and land transport, with door-to-door delivery worldwide. We offer specialized component transportation solutions, including reinforcement for extra-wide components and nighttime transportation.

Installation and Acceptance

A professional team completes module assembly within 48 hours, providing a welding quality inspection report (compliant with AWS D1.1) and coating thickness test records. 24 quality inspections are completed before delivery, including load and airtightness tests.

III. Corporate Strength: Certifications, Case Studies, and After-Sales Guarantee

Qualifications and Certifications

We are certified by the Australian SCA (compliant with AS/NZS 5131), the European Union EN1090 (CE mark), and ISO 9001 quality management system. Our products are tested by the National Steel Structure Engineering Quality Supervision and Inspection Center and comply with GB 50017-2017 standards. Typical Case Studies

Raffles City Hangzhou: Utilizing a steel tubular concrete frame structure, with a total steel consumption of 96,000 tons, the construction period was shortened by 8 months compared to traditional solutions, earning it the China Steel Structure Gold Award.

Wanda Plaza, Cangshan District, Fuzhou: Utilizing support-free and formwork-free composite floor slab technology, the project reduced construction costs by 25% and won the Third Prize of the Fujian Science and Technology Progress Award.

Guangzhou East Tower: A 530-meter super-tall steel structure, designed through BIM collaboration, achieved tolerance control of ≤5mm and won the Lu Ban Award.

After-Sales Service: We offer a 10-year structural warranty, a 5-year equipment warranty, and a 72-hour global fault response. We regularly provide maintenance guidelines (such as coating inspection intervals and photovoltaic panel cleaning frequency) to extend product lifespans to over 30 years.

IV. Business Cooperation Policy: Transparent, Flexible, and Cost-Effective

Packaging and Logistics: Components are secured with steel strapping and internally coated with EPE cushioning, resulting in a sea freight breakage rate of less than 0.3%. We also provide temporary storage for components at the yard, with 60-day free storage fees. Minimum Order Quantity and Pricing

Performance Verification

Third-party testing reports (such as SGS energy-saving ratings and China Earthquake Administration simulated vibration test data) are available. Customers can schedule factory and model room visits to verify product performance.

Why Choose Us

Shijiazhuang Eiffel Steel Structure Co., Ltd.

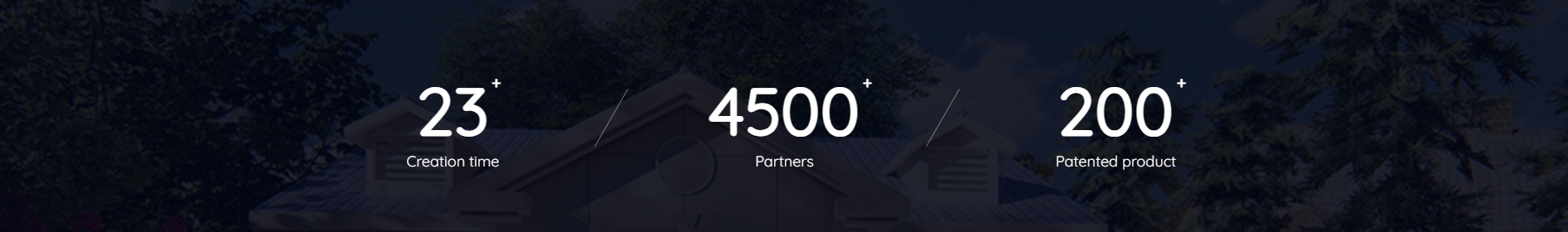

Shijiazhuang Eiffel Steel Structure Co., Ltd. is an enterprise dedicated to researching and developing new energy-saving and environmentally friendly houses and construction methods. We always adhere to the values of honesty and quality first, and position ourselves as a leader in high-quality steel structure villa construction. We combine emerging foreign technologies with the actual domestic market and provide customers with one-stop services for prefabricated buildings such as design, production, interior decoration, and whole house customization. The prefabricated buildings produced by the company are widely used in office buildings, villas, rural courtyards, estate clubs, tourist attractions, homestays, hotels, public facilities, etc.

At present, the company is centered in Shijiazhuang, Hebei Province, with products radiating to regions such as Beijing, Tianjin, Hebei, Shanxi, Shandong, Henan, Liaoning, Mongolia, Jiangsu, Sichuan, and Guangxi, and exported to overseas markets. Adhering to the quality demand of "building a century old villa, choose Eiffel", we strive to create an excellent brand of prefabricated buildings.

House building process

Helping customers maximise value with consistent excellence