Modular light steel villa with prefabricated structure

Modular light steel villas with prefabricated structures reimagine the possibilities of future residential and commercial spaces. As an innovator in modular construction, we specialize in providing efficient and environmentally friendly prefabricated light steel villa solutions for residential, commercial, and cultural tourism projects.

Introduction Of Light Steel Frame Houses In Earthquake-prone Areas

Modular light steel villas with prefabricated structures reimagine the possibilities of future residential and commercial spaces. As an innovator in modular construction, we specialize in providing efficient and environmentally friendly prefabricated light steel villa solutions for residential, commercial, and cultural tourism projects.

I. Core Product Advantages: Materials, Parameters, and Differentiated Design

Structural System and Materials

The main structure is constructed of Q345B high-strength steel, meeting GB/T 700-2006 standards, with a tensile strength of ≥375 MPa. Combined with an AZ150-grade galvanized steel coating, it offers corrosion resistance of over 30 years. The wall system consists of a double-layer 140mm light steel frame filled with graphite polystyrene insulation board (thermal conductivity ≤ 0.032 W/(m·K)), and is clad with either carved metal panels or wood-grain cement cladding, offering both aesthetics and durability. The floor system utilizes an 89mm truss beam structure with a load capacity of 350 kg/m2. Tested by the China Academy of Building Research, it meets the standards for earthquake resistance of magnitude 8 and wind resistance of magnitude 12. Glass Fiber Cotton and Moisture-Proofing System

50mm thick glass fiber cotton (bulk density ≥ 40kg/m³) with a thermal conductivity ≤ 0.045W/(m·K) is combined with 0.35mm moisture-proof breathable paper to form a highly effective thermal insulation layer. The breathable paper's special microporous structure allows for free passage of water vapor while preventing liquid water from penetrating, ensuring the building remains dry over time.

Modular Features and Eco-Integration

Fast Construction: Utilizing bolted connection technology, on-site installation speeds reach 250 square meters per day, shortening construction time by 45% compared to traditional construction.

Smart Control: Optional LoRa IoT modules enable remote control of lighting, temperature, humidity, and security systems via an app.

Renewable Energy: Integrated solar photovoltaic panels (280W/m²) and a ground-source heat pump reduce operating energy consumption by 35%.

II. Customized Service Process: Full-cycle management from requirements to implementation

Requirements communication and solution design

BIM digital modeling services are provided, allowing customers to adjust floor heights, column spacing, and functional zoning (e.g., raised living rooms, open kitchens) online. Optional materials (fluorocarbon sprayed aluminum/dark gray fluorocarbon paint) and special structures (cantilevered viewing platforms, sunken courtyards) are available. Our professional team provides design proposals within 48 hours, utilizing 3D visualization tools to achieve millimeter-level accuracy.

Production and Logistics

Utilizing an intelligent production line, component processing accuracy is ±2mm. Production lead times are 25 days for standard modules and 35 days for custom modules. We support sea and land transport, offer reinforced transportation solutions for extra-wide components, and provide door-to-door delivery worldwide. Our breakage rate is less than 0.2%.

Installation and Acceptance

Our professional team completes module assembly within 72 hours and provides a welding quality inspection report (compliant with AWS D1.1 standards) and coating thickness test records (≥80μm). 32 quality inspections are completed prior to delivery, including load testing, airtightness testing, and optical performance verification.

III. Corporate Strength: Certifications, Case Studies, and After-Sales Guarantee

Qualifications and Certifications

Awarded the China Steel Structure Gold Award, EU CE certification, and US UL 752 safety rating. The product is ISO 9001 quality management system certified and complies with T/CCMSA 20108-2019 standards, achieving A++ energy-saving performance as specified in GB/T29734.

Recommended Cases

Guangxi Mingyang Industrial Park Scenic Area Villa: Adopting a Chinese country-style, the 56.3-square-meter building was constructed using dry construction, with the main structure installed in 7 days. It blends seamlessly with the surrounding landscape and was named "Guangxi's Most Beautiful Tourism Supporting Building."

Hainan Boao Forum Supporting Villa: Utilizing a typhoon-resistant structural system, it has been tested to withstand force 14 winds and won the First Prize of the Hainan Provincial Science and Technology Progress Award.

Chongzuo Self-Built Light Steel Villa: This 200-square-meter project utilizes OSB (European Pine Board) and glass wool composite walls. Construction took 28 days, 50% shorter than traditional brick-concrete structures.

After-Sales Service: We offer a 50-year structural warranty, a 10-year equipment warranty, and 24-hour global fault response. We provide regular maintenance guidance (such as coating inspection intervals and photovoltaic panel cleaning frequency) to extend the product's service life to over 50 years.

IV. Business Cooperation Policy: Transparent, Flexible, and Cost-Effective

Packaging and Logistics

Components are secured with steel strapping and internally protected with EPE cushioning film, resulting in a sea freight breakage rate of less than 0.3%. Temporary storage of components is available at the warehouse, with 60-day free storage fees.

Minimum Order Quantity and Pricing

Performance Verification

Third-party testing reports (such as SGS energy-saving ratings and simulated vibration test data from the China Earthquake Administration) are available. Customers can schedule factory and model room visits to verify product performance.

Why Choose Us

Shijiazhuang Eiffel Steel Structure Co., Ltd.

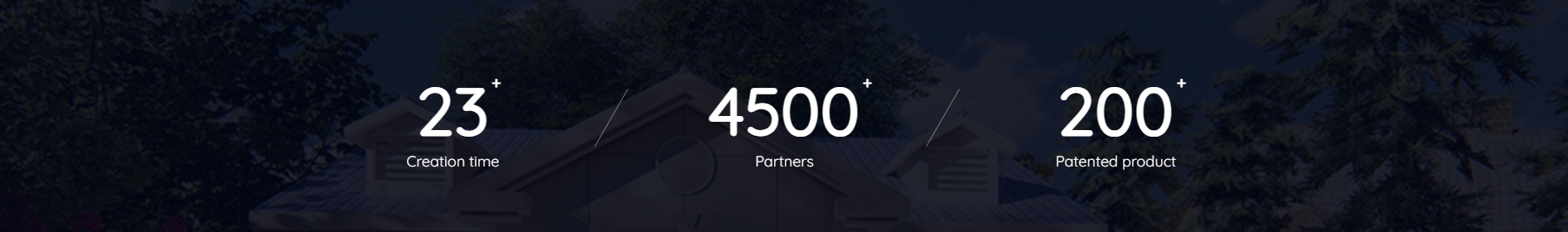

Shijiazhuang Eiffel Steel Structure Co., Ltd. is an enterprise dedicated to researching and developing new energy-saving and environmentally friendly houses and construction methods. We always adhere to the values of honesty and quality first, and position ourselves as a leader in high-quality steel structure villa construction. We combine emerging foreign technologies with the actual domestic market and provide customers with one-stop services for prefabricated buildings such as design, production, interior decoration, and whole house customization. The prefabricated buildings produced by the company are widely used in office buildings, villas, rural courtyards, estate clubs, tourist attractions, homestays, hotels, public facilities, etc.

At present, the company is centered in Shijiazhuang, Hebei Province, with products radiating to regions such as Beijing, Tianjin, Hebei, Shanxi, Shandong, Henan, Liaoning, Mongolia, Jiangsu, Sichuan, and Guangxi, and exported to overseas markets. Adhering to the quality demand of "building a century old villa, choose Eiffel", we strive to create an excellent brand of prefabricated buildings.

House building process

Helping customers maximise value with consistent excellence