Modular prefabricated luxury container house

The modular prefabricated luxury container house reimagines the luxurious living experience with an industrial aesthetic. As an innovative leader in modular construction, we focus on deeply integrating industrial aesthetics with luxury living needs, providing disruptive architectural solutions for high-end residences, commercial complexes, and distinctive cultural and tourism projects.

Modular prefabricated luxury container house

The modular prefabricated luxury container house reimagines the luxurious living experience with an industrial aesthetic. As an innovative leader in modular construction, we focus on deeply integrating industrial aesthetics with luxury living needs, providing disruptive architectural solutions for high-end residences, commercial complexes, and distinctive cultural and tourism projects.

I. Core Product Advantages: Materials, Parameters, and Differentiated Design

Structural System and Materials

The main structure is constructed of Q355B high-strength galvanized steel with a wall thickness of 1.5mm and a yield strength of ≥550MPa. It utilizes a sixth-generation hot-dip galvanizing process (150μm zinc layer) and has demonstrated no corrosion after over 3000 hours of salt spray testing. The wall system consists of a double-layer 100mm light steel keel, interfilled with 75mm graphite polystyrene insulation board (thermal conductivity ≤0.032W/(m·K)), and covered with 0.4mm fire-resistant sandwich panels, meeting Class A1 fire protection standards. Measurements by the China Academy of Building Research show that the wall's thermal conductivity is as low as 0.28W/(m·K), resulting in over 65% energy savings compared to traditional brick-concrete buildings. 3D Design and Ecosystem Integration

Using BIM 3D modeling and parametric design software, the project achieves full digitization from concept drawing to construction drawing. For example, the "PV14house" project in Shanghai utilizes an adjustable steel frame to achieve complex designs such as "floating staircases" and "panoramic floor-to-ceiling windows," increasing space utilization by 30% for a 120-square-meter apartment with an accuracy of less than 3mm. The "Light Steel Villa DIY System" allows customers to freely combine six color palettes and 24 exterior modules, resulting in real-time rendering.

Breakthrough Performance and Luxurious Features

Fast Construction: Modular components can be assembled on-site at a speed of 350 square meters per day. A demonstration project in Shanghai set a record by completing the main structure in just three days.

Intelligent Control: Integrated LoRa IoT modules enable remote control of temperature, humidity, lighting, and security systems via an app. Combined with double-layer galvanized steel panels and a glass wool interlayer, the project boasts thermal insulation performance that exceeds national standards by twice.

Renewable Energy: Optional solar photovoltaic panels (280W/square meter) and ground-source heat pumps reduce operating energy consumption by 40%.

II. Customized Service Process: Full-Life Cycle Management from Demand to Implementation

Demand Communication and Solution Design

A 3D visualization configuration tool is provided, allowing customers to online adjust functional areas (such as a raised living room or open kitchen), select materials (fluorocarbon sprayed aluminum panels or dark gray fluorocarbon paint), and special features (cantilevered viewing platforms or sunken courtyards). Our professional team will provide a design proposal within 48 hours, integrating BIM modeling to achieve millimeter-level accuracy.

Production and Logistics

Utilizing an intelligent production line, component machining accuracy is ±2mm. The production cycle is 25 days for standard modules and 35 days for custom modules. We support sea and land transport, provide reinforced transportation solutions for extra-wide components, and offer door-to-door delivery worldwide, with a breakage rate of less than 0.2%.

Installation and Acceptance

Our professional team completes module assembly within 72 hours and provides welding quality inspection reports (compliant with AWS D1.1 standards) and coating thickness test records (≥80μm). 32 quality inspections are completed before delivery, including a magnitude 8 seismic test, airtightness testing, and optical performance verification.

III. Corporate Strength: Certifications, Case Studies, and After-Sales Guarantee

Qualifications and Certifications

Awarded the China Steel Structure Gold Award, EU CE certification, and US UL 752 safety rating. Products are ISO 9001 quality management system certified and comply with T/CCMSA 20108-2019 standards, achieving energy-saving performance of A++ as specified in GB/T29734.

References

Shanghai's "PV14house" project: Combining containers with a wooden structure, the project features a floating staircase and panoramic floor-to-ceiling windows, winning the "China Modern Residential Design Award."

Moganshan Xidi 99 Resort: The 13 container villas achieve a 52% reduction in full-cycle carbon emissions compared to traditional buildings, and construction water consumption is reduced by 60%.

Qingdao TEU Container Tribe: The commercial complex, comprised of over 200 containers, boasts an annual passenger flow exceeding 3 million, driving a 40% increase in the surrounding commercial value.

After-Sales Service: A 50-year structural warranty, a 10-year equipment warranty, and 24-hour global fault response are provided. Regular maintenance guidelines (such as coating inspection intervals and panel cleaning frequency) are provided to extend the product lifespan to over 50 years.

IV. Business Cooperation Policy: Transparent, Flexible, and Cost-Effective

Packaging and Logistics

Components are secured with steel strapping and internally protected with EPE cushioning film, resulting in a sea freight breakage rate of less than 0.3%. Temporary storage of components is available at the warehouse, with 60-day free storage fees.

Minimum Order Quantity and Pricing

Performance Verification

Third-party testing reports (such as SGS energy-saving ratings and simulated vibration test data from the China Earthquake Administration) are available. Customers can schedule factory and model room visits to verify product performance.

Why Choose Us

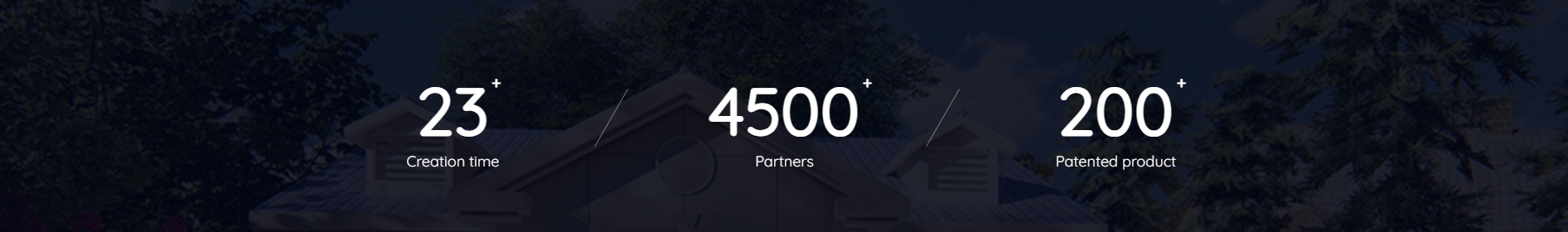

Shijiazhuang Eiffel Steel Structure Co., Ltd.

Shijiazhuang Eiffel Steel Structure Co., Ltd. is an enterprise dedicated to researching and developing new energy-saving and environmentally friendly houses and construction methods. We always adhere to the values of honesty and quality first, and position ourselves as a leader in high-quality steel structure villa construction. We combine emerging foreign technologies with the actual domestic market and provide customers with one-stop services for prefabricated buildings such as design, production, interior decoration, and whole house customization. The prefabricated buildings produced by the company are widely used in office buildings, villas, rural courtyards, estate clubs, tourist attractions, homestays, hotels, public facilities, etc.

At present, the company is centered in Shijiazhuang, Hebei Province, with products radiating to regions such as Beijing, Tianjin, Hebei, Shanxi, Shandong, Henan, Liaoning, Mongolia, Jiangsu, Sichuan, and Guangxi, and exported to overseas markets. Adhering to the quality demand of "building a century old villa, choose Eiffel", we strive to create an excellent brand of prefabricated buildings.

House building process

Helping customers maximise value with consistent excellence