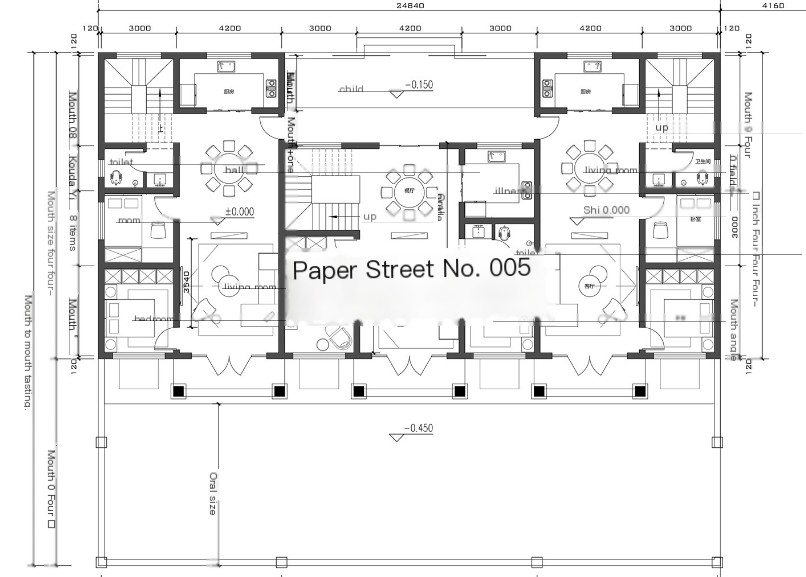

Design drawings of a two-story European-style light steel villa in Kaizhou

Drawing No. 001984

Building Area: 338.00 m2

Width: 24.80 m

Number of Bays: 7

Number of Floors: 2

Structure: Brick-concrete structure

Construction Cost: 500,000 RMB

Land Area: 288.00 m2

Depth: 13.70 m

Number of Bedrooms: 6

Architectural Style: Popular and refined, European style, practical, symmetrical

City: Chongqing/Chongqing Municipality/Kaixian County

Architectural Features: Terrace, flat roof, courtyard, north-facing staircase, 7-8 bays, 6-7 bedrooms

The house occupies a regular area and has two floors. The overall design blends traditional European and modern architectural elements, with flowing lines, a stylish appearance, and a meticulous layout, all revealing the designer's spatial expression. Let's take a closer look at the details of this villa.

The two-story villa covers an area of approximately 228 square meters, with 6 bedrooms, 2 living rooms, 1 kitchen, 1 bathroom, and 2 balconies, suitable for a family, and also providing accommodation for occasional visits from friends and family.

This light steel villa is roughly divided into four systems:

Foundation System: The foundation of the light steel villa requires ensuring "three levels and one connection" before construction begins. "Three levels and one connection" refers to the prerequisites for starting basic construction projects, specifically: water supply, electricity, road access, and a level site. Appropriate anchors and pull-out resistors are used to ensure a reliable connection between the main structure and the foundation.

Roofing System: The roof trusses are assembled from light steel components, typically using triangular trusses, which easily allows for various complex roof shapes. An insulation layer is also added to the roof for better temperature control. Asphalt shingles are commonly used on the exterior, providing excellent waterproofing and enhancing aesthetics and quality.

Wall System: Utilizing a two-panel, one-core construction, the walls of light steel houses are thinner, increasing usable floor area by approximately 10%-15% compared to traditional houses. Centrifugal glass wool is filled in the wall core, providing excellent sound insulation and thermal insulation. Tensile panels are used on both sides to significantly strengthen the roof's surface, making the light steel structure more robust and stable.

Floor System: The floor beams now use high-strength hot-dip galvanized C-shaped and U-shaped steel components produced by FM300 equipment, covered with strictly moisture-proof and corrosion-resistant structural panels to form a robust floor system.